Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Tel:15662735099

Add:Shandong Zhangqiu Zaoyuan Economic Development Zone

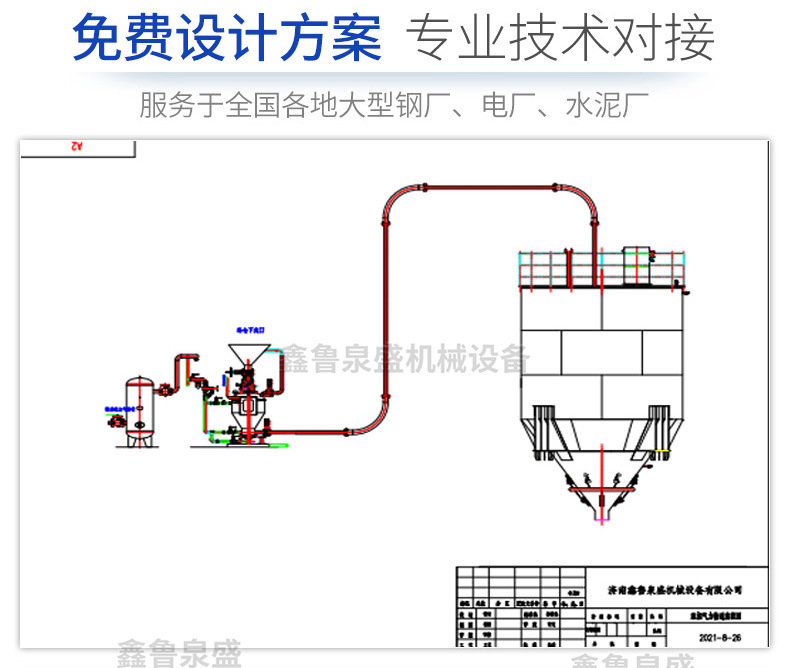

The pneumatic conveying system is mainly used for conveying dry powder and granular products with air flow as the carrier. Generally speaking, the airflow is ordinary air, but in some special conditions, dry, cooled, heated air or inert gases such as nitrogen can also be used as transport airflow. According to this basic structure, the product (solid particles) is carried by the airflow through a certain length of pipeline after being mixed with the airflow. This pipeline is connected to the feeder or cyclone separator to separate gas and product.

The pneumatic conveying system consists of four components:

1. Source power - blower, screw fan, compressor, exhaust fan or vacuum pump, used to generate airflow.

2. Feeder - Rotary valve, Venturi tube, screw feeder, air duct or other feeding device, which adds particles into the airflow under control.

3. Conveyor lines - straight pipes, bent pipes, and diversion valves.

4. Separators - cyclone separators, feeders, filters, feeders or silos/pipelines, separate particles from airflow.

There are two ways of airflow delivery system:

1. Dilute phase conveying (sparse phase flow) - With high gas flow rate, low product conveying capacity, low particle content, and a mass flow ratio of approximately 0-15, the product is suspended in the gas flow. Negative pressure -0.5 bar -1.0 bar Advantages:

Low pressure

low cost

Flexible/Universal

A dilute phase positive pressure pneumatic conveying system (also known as a positive pressure airflow conveying system or pneumatic conveying system) is a system that uses the airflow output by a blower (such as a Roots blower) as a carrier to unload bulk powder particles into a pipeline for pressure conveying. The positive pressure value of the dilute phase positive pressure pneumatic conveying system is less than 0.15 Mpa, the gas-solid ratio is 5-20, the capacity of the positive pressure pneumatic conveying system can reach 60 tons/hour (single air transport line), and the conveying distance can reach 400 meters.

B negative pressure pneumatic conveying system (also known as negative pressure air conveying system or negative pressure air conveying system) is a vacuum pump (such as Roots or water ring) that generates vacuum to suck bulk powder materials into designated equipment with negative pressure air flow. The negative pressure value of the negative pressure pneumatic conveying system is less than 0.06Mpa, and the gas-solid ratio is 1 to 15. The high vacuum pneumatic conveying system consists of a receiving tank, a filtering device, and a vacuum pump. The vacuum pump sucks the material into the receiving tank, filters the gas, and discharges it, and the material falls into the receiving hopper. It belongs to the negative pressure high concentration pneumatic conveying method, with the characteristics of long conveying distance (<60 meters) and gas-solid ratio of 2-8. The negative pressure pneumatic conveying system has continuous and uniform feeding, and can be conveyed by pressure conveying. Difficult to supply materials such as garbage, wood chips, and slender fibers, it can achieve centralized transportation from several places to a single location and has a certain mixing function. At the same time, the capacity of the air delivery system can reach 30t/h (single conveyor line).

Dense phase conveying - low gas flow rate, high product conveying capacity, high particle content, mass flow ratio higher than 15, block like movement, positive pressure+110 bar